The Dragline Story

Early Draglines - 1940s

In the 1940s small draglines were used to remove overburden. They typically had bucket sizes less than 2 1/4 cubic yards, booms less than 60 feet, were powered by diesel engines and rolled on caterpillar tracks. These draglines aimed to provide a steady output of coal around 8,000 tons per week until the bigger Bucyrus-Erie 9W dragline could be delivered from the USA and production could be increased to 20,000 tons per week. Most of these small draglines became obsolete during the 1950s except the Osgood 1006, which remained in service until the early 1970s.

Ruston 55

Harman Type M

North West (2 variations)

Osgood 1006

Bucyrus-Erie 9W - 1950s

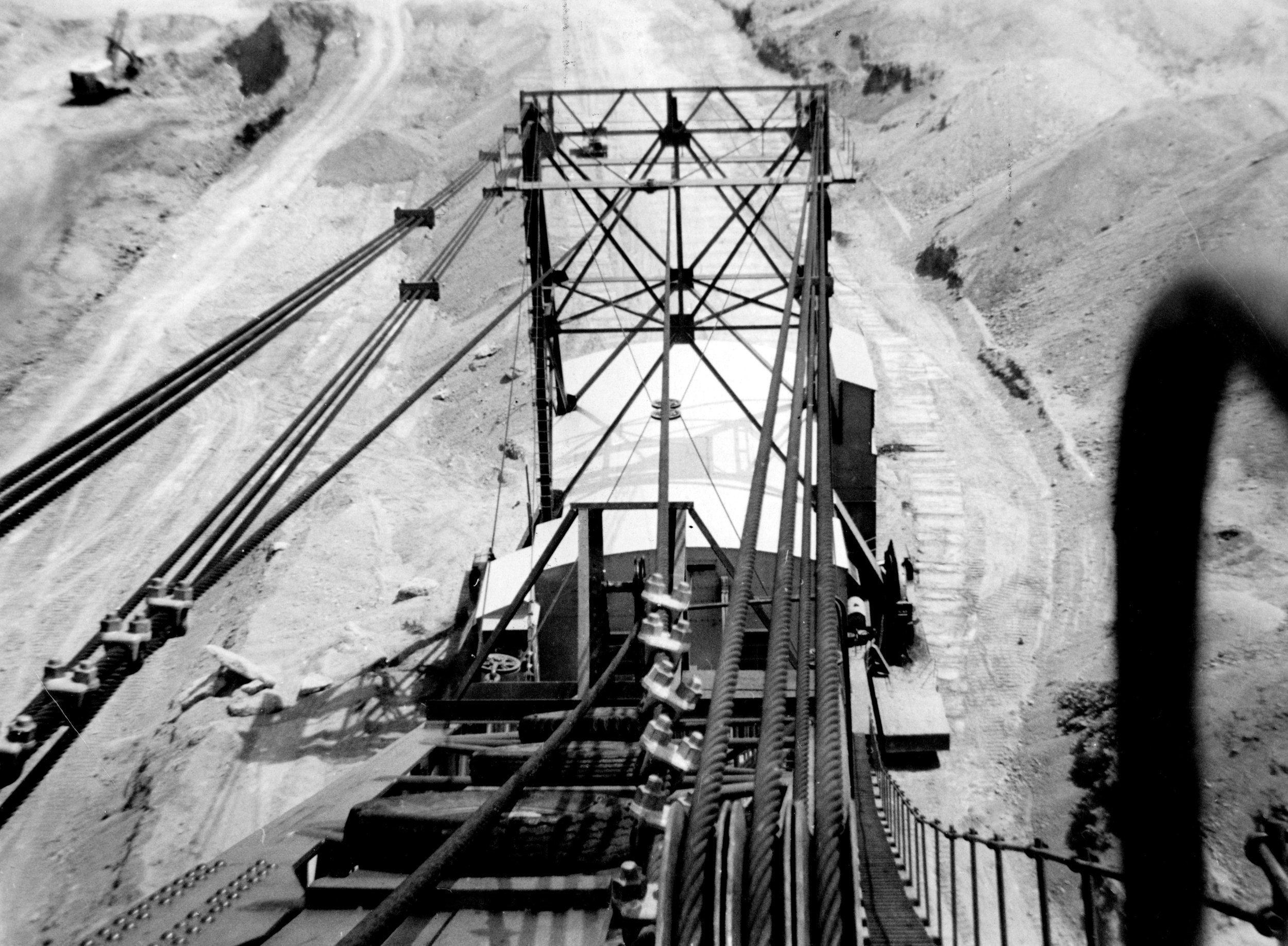

The 9W dragline arrived at Leigh Creek from the USA, was assembled on site and commenced operation in 1952. At the time it was the largest walking dragline in the southern hemisphere. It was electrically powered and could be configured with a 160 ft boom and 10 cubic yard bucket or a 200 ft boom and 7 cubic yard bucket. The 200 ft boom towered 125ft above the ground - almost the same height as the highest building constructed in Adelaide (132 ft). The 9W operated at Telford until late 1955 when it walked to Northfield. The 6 mile journey took two weeks. The 9W dragline remained in service until 1982. It is estimated that during its lifetime in dug almost 30 million cubic yards of overburden.

9W Base Tub Repair - 1960

The introduction of the 9W dragline, and other more efficient electric excavators, required a much larger power station. Plans were drawn up in the late 1940s; construction of a new coal-fired, steam power station commenced at Northfield in 1950. The first electricity was generated early in 1951 - just in time for the 9W to be commissioned.

Ruston Bucyrus 5W

In 1951 an additional two 5W walking draglines where also ordered. Smaller versions of the 9W these draglines were also electric and could be configured with a 120 ft boom and 5 cubic yard bucket or a 135 ft boom and 4 cubic yard bucket. While the 9W removed overburden, the 5Ws role was to remove the layer of shale separating the upper and lower seams of coal in the northern basin. The first of the 5W draglines was commissioned in 1953 and the second in 1955. Together the 9W and 5W draglines removed the requirement to cart overburden by truck.

Bucyrus Erie 770B Dragline - 1960s

The 770B dragline was official commissioning by Lady Playford on 22 Nov 1961. At the time it was the largest dragline of its type operating in Australia and twice the size of anything working at Leigh Creek. As tall as a 12 story building the huge 900 ton machine had a 235 ft boom and 18 cubic yard bucket.

770B Assembly at Northfield - 1960/61

A team of local men, consisting of welders, mechanical and electrical fitters, riggers, tradesmen’s assistants and painters, took 21 weeks to complete the assembly of 770B. The first piece placed was the centre section of the base tub; other sections of the tub were then added, lined up and welded together. Concurrently, with the assembly of the tub, the boom and mast were assembled. Next the erection of the sub-revolving frame, the revolving frame girders and main machinery. The A-frames were then placed into position using the 75ft boom of the 55-RB crane before the housing framework and sheeting was added. The mast was attached and was then used as a crane to lift the boom into position. Then the suspension ropes between the mast and the boom were fitted. In the meantime, some 5,000 feet of electrical wiring was installed, and painters brushed and sprayed 400 gallons of paint. The boom was raised, wire ropes and bucket fitted, while the electrical circuits and machinery were checked. After a short period of testing the machine was ready for commissioning.

At a ceremony on 22 November 1961, Lady Playford unveiled a plaque commemorating the occasion of the 770-B Dragline being officially commissioned. It began work in stripping overburden in Lobe D, Northfield.

“ They Walk by Night” - Adelect Feature February 1968

770B Maintenance

Page 736 - 1970s

The Page dragline was purchased in 1968, assembled at Northfield during 1970 and commissioned in 1971.

It was similar in size to the 770B with a 230ft boom and 17 cubic yard bucket.

Page Assembly at Northfield - 1970

The Page Dragline boom collapse occurred in July 1976. The Page had recently walked to a new site at the southern end of Lobe B to start removing the overburden for a new cut. This was part of the mine expansion required to double coal production for future supply of the new Northern Power Station to be built at Pt Augusta. Early on a Sunday morning, during night shift, Adrian Lang and Rene Van Zetten crewed the Page Dragline as it rehandled wet, muddy sand that was dripping water. The action of dragging the bucket through the previously dug material allowed it to completely fill to the point of overfill. The excess weight in the bucket bent the boom past the point of return and it kept flexing until it folded back on itself.

In hindsight, it is not unreasonable to surmise that the construction of the boom may have been a contributing factor. Unlike the boom on the 770 Dragline, which was made of tubular pipe, the boom cross pieces on the Page Dragline were made of angle iron. This angle was made to a different specification than Australian steel and because it was not as “flexible” there was potential for problems of fatigue and welds cracking. At the time the Page was purchased from the USA, Peter Mussared (Manager Leigh Creek) was so concerned about the strength of the boom he insisted it be replaced by a stronger one. He also ordered some spare lengths of steel in case the boom failed. Despite this, as foreseen, the Page had continual problems with the welds cracking where the cross beams were welded to the main T section of the boom assembly. In the early days the boom was often lowered for maintenance and these angle iron cross pieces replaced with more “friendly” steel.

Luckily, or through good foresight and planning, when Peter Mussared heard from Ray Gray (Manager Leigh Creek) and the ETSA General Manager that the boom had collapsed, he directed them to the spare parts available in the Leigh Creek Stores. The entire team of ETSA welders and boilermakers in the Maintenance Workshops were tasked with the repair which included replacing most parts of the boom, except the main beams. The repair is reported to have cost over $100,000 (Klaassen) which is equivalent to about $500,000 in 2021.

Draglines continued to be used to remove overburden until mid 1978 when they were replaced by truck and shovel operations. They were progressively sold off and by 1991 only two remained. The 9W was retired in 1982 and exhibited as a tourist attraction until it was sold for scrap when the mine was closed in 2016. The Page worked on into the 1990s and was used in a unique program to help rehabilitate overburden dumps.

2007 - Scrapping Page 736 Dragline