Mining in the 1940s

In August 1941 exploration of the Telford and Northern basins commenced. Boreholes were drilled on a grid pattern to determine coal locations and depths. This drilling determined the viability of open cut mining in both areas. Later, with the assistance of Commonwealth geophysicists, it was determined that the probable coal reserves at Leigh Creek were 380,000,000 tons. The great bulk of this coal existed in the Telford basin, or Lobe B.

The Engineering and Water Supply Department commenced open cut mining at Lobe B, or “The Telford Cut”, in 1943. To help establish the cut, two second hand 2 ½ cubic yard draglines were purchased. One of these machines had previously been used to excavate the Appleton Dock in Melbourne. By 1945 four excavators, a power shovel and a large bulldozer were working in the mine. Initially, both overburden removal and coal hauling were done by private contractors using a variety of small trucks, mainly in the 4-6 ton range. By 1948, when control of the field was transferred to The Electricity Trust of South Australia, the mechanical fleet had grown again with the addition of another three shovels, four bulldozers and fifteen Mack trucks. Additionally, a 9W Bucyrus-Erie walking dragline with a 10 cubic yard bucket had been ordered from the USA and was expected to arrive in 1950. This dragline would remove the need to haul overburden clear of the mining cut and make it possible to almost triple the mines output. By the end of the decade mining had also started at the Northern Field, including development of new railway siding for loading coal and a new crushing and screening plant. A 3,000 kW steam power station was also under construction to produce the power for the operation of the 9W dragline and other electric mining equipment.

LeTourneau Model C Tournapull

Wheel tractor-scrapers (also known as a Tournapulls) were used to remove overburden at Telford and Northfield.

The scraper was often assisted by a tow tractor to load up to 15 tons at a time.

Draglines

In 1943 the first draglines arrived at the coalfield. Three small draglines were used to remove overburden; a 2 1/4 cubic yard Harman, a 1 cubic yard Ruston and a 3/4 cubic yard Harman. These small draglines did not have the reach to move the overburden far enough away from the coal seam so they were used to load trucks that carried it to dumping areas. In these early years the majority of the overburden was used to build levees that diverted local creeks and floodwaters away from the open cut.

Excavating Shovels

The first shovel to work at Telford was a tiny 3/8 cubic yard Harman powered by a 60 hp caterpillar engine.

North West

By 1948 two North West 1 1/2 cubic yard shovels were operating at the coalfield.

Thew-Lorain

The Thew-Lorain 2 cubic yard shovel arrived at the coalfield in 1948.

Tractors & Bulldozers

Tractors and bulldozers played an important role in mining operations. They towed equipment, ripped shale, moved overburden, constructed access roads and much more. In 1944 the first D-8 Caterpillar tractor was equipped with both a bulldozer and rooter.

Trucks

Initially, both overburden removal and coal hauling were done by private contractors using a variety of small trucks, mainly in the 4-6 ton range. The first Mack trucks, with increased capacity of 10 ton, were purchased by the E&WS prior to 1948. The Mack fleet was increased to 27 trucks during 1948 and 1949. Private contractors where phased out by 1957 and the last of the Macks remained in service until 1966.

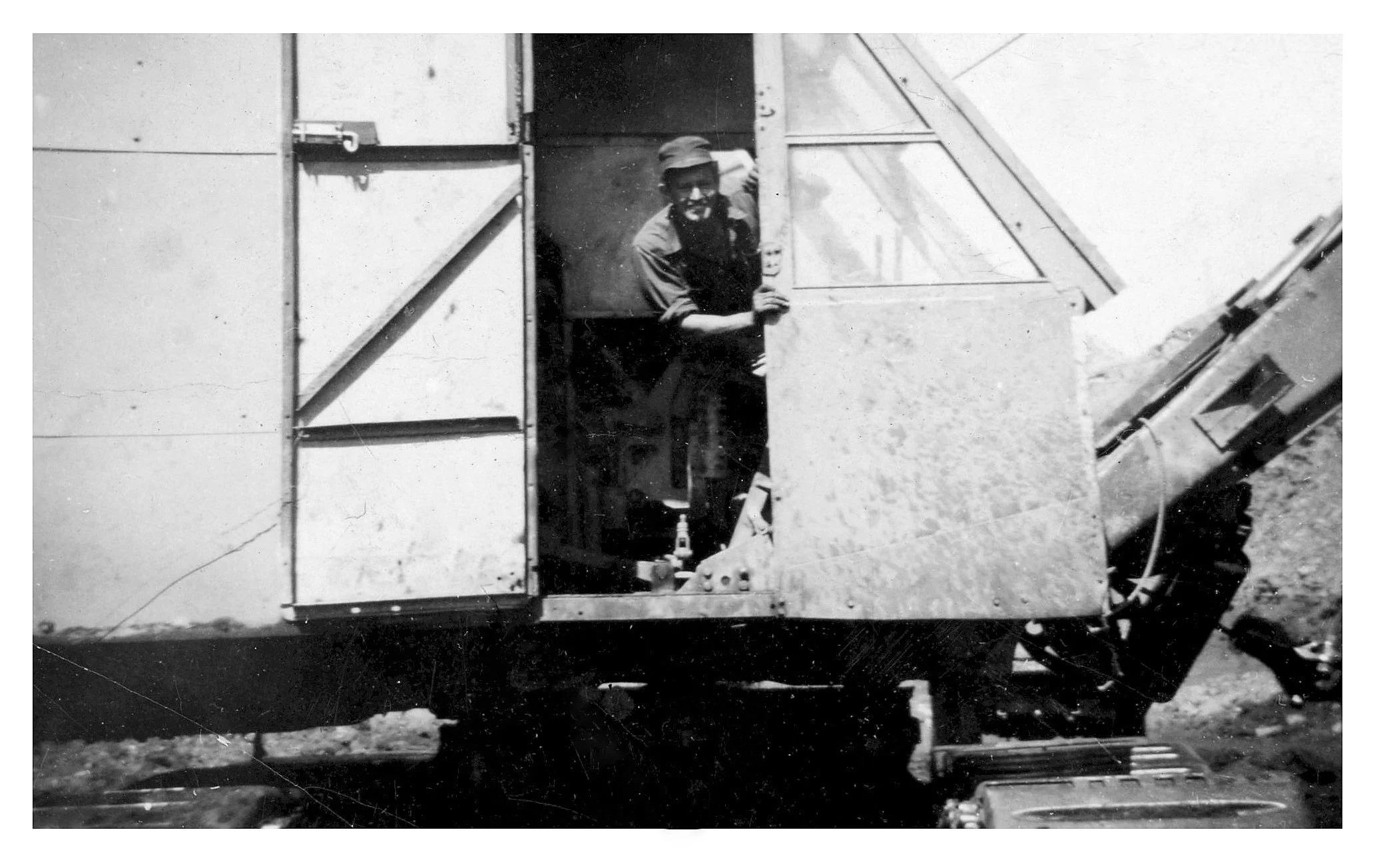

Crushing & Loading

In 1944 ungraded coal winnings were loaded onto trains by dumping down a chute directly into the rail carriages. Any large lumps were broken up by hand using picks and sledge hammers. As the use of coal increased, customers demanded graded winnings, and in 1945 a temporary grading plant was constructed. This plant crushed and graded winnings to a maximum size of 6 inches and then used a shaker to grade it into three different sizes; lump coal (40%), stoker coal (40%) and fines (20%). The fines were difficult to sell so they were subsequently stockpiled at Telford to provide contingency should demand exceed production. In 1947 foundations were laid for a bigger permanent crushing and grading plant. Within two year this plant was operational and could grade winnings into four sizes. However, by 1948 coal winnings from Northfield were being transported by truck five miles to the Telford siding and plans were already being developed to build a new siding, crushing and grading plant and storage facilities at Northfield.

Wooden coal storage bins were added to the Telford loading plant in 1952

The Coal storage bins were destroyed by fire in February 1963 (Jack Colmer)